Modular Design: Accelerating Builds

- ✓ Adaptability to various sizes

- ✓ Streamlined setup processes

- ✓ Reduced labor requirements

What if you could complete your construction projects faster and with higher quality? Aluminum formwork systems are revolutionizing the industry by providing innovative solutions that enhance efficiency and reduce costs. Let’s explore how these systems can impact your project timelines!

Aluminum formwork streamlines project timelines through its modular design, prefabrication integration, and efficiency benefits.

In today's fast-paced construction environment, every project leader is keenly aware that project timelines can make or break a project. One of the most effective ways to streamline your schedule is by utilizing lightweight aluminum formwork systems. But what exactly is aluminum formwork, and how does it influence construction timelines? Let’s dive into the details!

Aluminum formwork is a reusable system made from lightweight aluminum panels, designed to hold wet concrete in place during the curing process. Unlike traditional formwork options, aluminum systems are not only durable but also easy to handle, making them a preferred choice for many construction professionals. With my experience at Concrete Slab Innovations, I’ve seen firsthand how these systems can transform project outcomes. For a comprehensive overview of how this technology has evolved and its benefits, you can refer to this review of aluminum formwork technology.

Aluminum formwork is a modern solution that addresses many challenges associated with traditional concrete formwork. Its lightweight design allows for easier handling and quicker assembly, which is crucial for keeping projects on track. In addition, the perfect fit of aluminum panels helps ensure that concrete is poured accurately, reducing waste and enhancing quality.

As a contractor or project manager, embracing aluminum formwork can significantly impact your scheduling efficiency. With its modular design, this system supports rapid adaptation to various project needs.

Modular design is at the heart of aluminum formwork systems. Each panel can be combined and configured in a multitude of ways, allowing for customized solutions tailored to specific project requirements. This flexibility not only enhances efficiency but also ensures that builders can respond quickly to design changes without compromising the overall timeline.

With modular design, you’re not just investing in formwork; you’re investing in a system that enhances overall project agility. Imagine completing phases of your build ahead of schedule—how would that affect your project's success?

Another critical aspect of aluminum formwork is its integration with prefabrication techniques. When components are manufactured off-site, the construction process becomes much more efficient. Prefabrication allows teams to focus on assembling rather than creating, leading to quicker timelines without sacrificing quality.

By embracing prefabrication alongside aluminum formwork, contractors like ourselves at Concrete Slab Innovations can achieve higher productivity while also fostering a safer work environment. The combination of these strategies truly supports modern construction goals.

As you consider the benefits of aluminum formwork, we want to know your thoughts! How likely are you to adopt aluminum formwork in your next construction project?

Aluminum formwork offers several key advantages, including superior durability, lightweight design for faster assembly and disassembly, and modularity for flexible configurations. These features contribute to significant time and cost savings, as well as improved concrete finishes and enhanced safety on site.

Modular design allows aluminum formwork panels to be easily combined and reconfigured to suit various project requirements. This adaptability streamlines setup processes, reduces labor needs, and enables faster progress through different construction phases, ultimately accelerating project timelines.

Prefabrication involves manufacturing formwork components off-site, which significantly reduces on-site labor and potential delays. This approach ensures higher quality control in a factory setting, leading to superior finishes and improved safety by minimizing work performed in potentially hazardous construction environments.

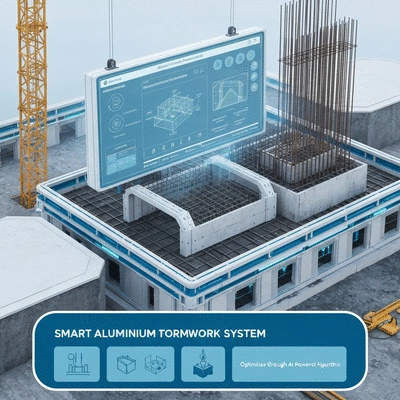

AI and smart systems are set to revolutionize aluminum formwork by optimizing configurations through data analysis, integrating real-time monitoring with sensors, and enabling customized solutions through technologies like 3D printing. These advancements promise to further enhance efficiency, quality, and sustainability in construction.

Project leaders should assess time savings (how much faster projects are completed), cost efficiency (reductions in labor and material costs), and quality assurance (improvements in concrete finishes and structural integrity). Focusing on these KPIs helps in understanding the tangible benefits of adopting aluminum formwork.

As we continue to navigate the ever-evolving landscape of construction, it's clear that aluminum formwork is at the forefront of innovation. With advancements in technology and design, the potential for lightweight aluminum systems is expanding rapidly. At Concrete Slab Innovations, we're excited to explore these developments and consider how they will shape the future of our industry.

One of the most promising areas of growth is the integration of artificial intelligence (AI) into aluminum formwork design. By leveraging AI, we can optimize formwork configurations and improve project outcomes. Imagine having a system that can analyze previous projects and suggest the most efficient formwork setups for your current job! This innovation will not only save time but also enhance the quality of our builds. For more detailed insights into AI's impact on construction and material science, you can explore research on AI applications in construction materials.

As technology progresses, several innovative trends are emerging in aluminum formwork. Here are a few that I believe will significantly impact our construction practices:

Embracing these trends will not only streamline our processes but also align us with a more sustainable and efficient construction model. The role of aluminum in sustainable construction is further highlighted in studies such as those discussing sustainable and economic applications of aluminum in construction.

Integrating construction technologies is essential for enhancing our performance metrics. Tools like Building Information Modeling (BIM) and project management software are becoming indispensable in our daily operations. At Concrete Slab Innovations, we advocate for using these technologies to improve collaboration and accuracy on-site.

When assessing the effectiveness of aluminum formwork, it’s crucial to consider the following metrics:

By focusing on these key performance indicators, we can better understand the impact of incorporating aluminum formwork into our projects.

As project leaders, it's essential to stay informed and proactive in adopting new technologies and methodologies. The shift toward aluminum formwork represents not just a trend but a significant evolution in our industry. Here’s how you can prepare for the future:

Before making the switch to aluminum formwork, consider the following questions:

By answering these questions, you can make an informed decision about whether aluminum formwork suits your upcoming projects.

Collaborating with industry experts, like the team at Concrete Slab Innovations, can provide invaluable insights. I encourage you to reach out to professionals who specialize in aluminum formwork to discuss your project requirements. They can offer tailored advice and help you navigate the implementation process.

Lastly, effective project management is crucial when introducing new systems. I recommend utilizing construction scheduling tools that allow for:

Implementing these strategies will pave the way for successful adoption of aluminum formwork, helping you achieve your project goals while embracing innovation!

Here is a quick recap of the important points discussed in the article:

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Consider this: the effective use of aluminum formwork can significantly streamline your construction

Consider this: the effective use of aluminum formwork can significantly streamline your construction

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a