Understanding Reinforced Concrete Slabs

Have you ever walked on a concrete floor and wondered about the engineering marvel that allows it to bear weight and withstand stress? Reinforced concrete slabs are more than just surfaces; they are the backbone of modern construction. Discover the essential knowledge that can elevate your understanding and application of these critical structures.

What You Will Learn

- The definition and significance of reinforced concrete slabs in construction.

- Different types of reinforced concrete slabs and their specific applications.

- Essential materials used in creating durable reinforced concrete slabs.

- Key installation techniques to ensure long-lasting slab performance.

- Common construction methods suitable for various project needs.

Key Elements and Techniques in Reinforced Concrete Slabs

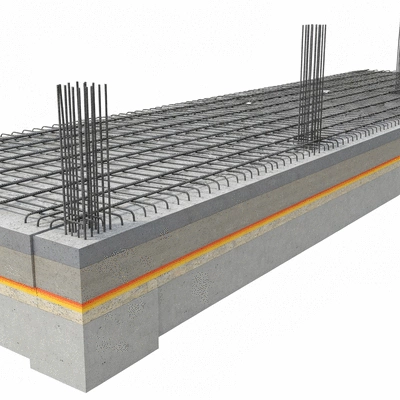

This visual outlines the fundamental components and common installation techniques essential for robust concrete slab construction.

Materials & Role of Steel Rebar

- ✓ Concrete Mix: Strength & durability.

- ✓ Steel Rebar: Tensile strength against dynamic loads.

- ✓ Proper Placement: Critical for performance.

Essential Installation Steps

- Site Prep: Level subgrade.

- Formwork: Shape slab.

- Reinforcement: Rebar placement.

- Pouring: Consistent coverage.

- Finishing: Smooth surface.

- Curing: Optimal strength.

Types of Reinforced Slabs

- ● One-Way: Loads in one direction.

- ● Two-Way: Loads in two directions, versatile.

- ● Flat Slabs: No beams, direct column support.

Common Construction Methods

- ◆ Traditional: Straightforward applications.

- ◆ Post-Tensioned: Long spans, enhanced strength.

- ◆ Slab on Grade: Residential, direct on ground.

- ◆ Elevated: Commercial, supported by beams/columns.

Understanding Reinforced Concrete Slabs

When diving into the world of construction, it's essential to grasp the foundation of your projects. Reinforced concrete slabs play a pivotal role in modern building design, providing the structural integrity and durability needed for both residential and commercial applications. But what exactly is a reinforced concrete slab, and why is it so crucial? Let’s explore!

What is a Reinforced Concrete Slab?

A reinforced concrete slab is a flat, horizontal surface made from concrete that has been reinforced with steel bars or mesh. This combination allows the slab to withstand various loads and stresses, making it a preferred choice in many construction projects. Have you ever walked on a concrete floor and thought about the engineering behind its strength? That's the magic of reinforced concrete at work! For a comprehensive guide on reinforced concrete structures, you can refer to the Indiana Department of Transportation's detailed chapter on Reinforced-Concrete Structures.

- Provides structural support for buildings

- Enhances durability and lifespan

- Accommodates various design requirements

At Concrete Slab Innovations, we emphasize the importance of understanding these slabs as they directly influence project outcomes. Whether you're an engineer, contractor, or project manager, knowing the basics can lead to more informed decisions during construction.

Types of Reinforced Concrete Slabs

Reinforced concrete slabs come in various types, each designed to meet specific needs and applications. Here are some common types:

- One-Way Slabs: These slabs are supported on two opposite sides and are primarily designed to carry loads in one direction.

- Two-Way Slabs: Supported on all four sides, these slabs can carry loads in two directions, making them highly versatile and efficient.

- Flat Slabs: A type of two-way slab without beams, they are directly supported by columns, allowing for flexible layouts.

Understanding these types can help you choose the right slab for your specific construction needs. Each type has its advantages, depending on factors like load distribution and the building's overall design. For further insights into the design considerations for concrete slabs, the WBDG provides guidelines for floor slabs in DoD facilities, which can be valuable for various projects.

Materials Used in Reinforced Concrete Slabs

Choosing the right materials is crucial for the performance and longevity of reinforced concrete slabs. The primary materials include:

- Concrete Mix: A well-prepared concrete mix is essential for achieving the desired strength and durability.

- Steel Rebar: Used for reinforcement, it provides tensile strength to counteract the concrete's natural weaknesses.

The Role of Steel Rebar in Reinforcement

Steel rebar is a critical component of reinforced concrete slabs. It absorbs tensile forces that concrete alone cannot withstand. The integration of rebar enhances the slab's ability to handle dynamic loads, improving overall safety. Have you considered how the placement of rebar can impact your slab’s performance? Proper placement is key!

Choosing the Right Concrete Mix for Durability

Not all concrete mixes are created equal. When selecting a mix for your slab, consider factors such as environmental conditions, load requirements, and desired lifespan. A high-quality mix can significantly enhance the durability of your slab, ultimately leading to fewer repairs and lower lifetime costs.

Understanding Load-Bearing Capacity in Slab Design

Load-bearing capacity is a vital aspect of slab design. It determines how much weight a slab can support without compromising its integrity. Understanding your project's specific requirements and working with professional engineers can ensure that your slab meets all safety standards. It’s about creating a solid foundation for your investment! For more detailed information on concrete pavement design and construction, the Federal Highway Administration offers an excellent reference on concrete pavement fundamentals.

Pro Tip

When selecting your concrete mix for reinforced slabs, consider incorporating additives such as superplasticizers. These can enhance workability without increasing water content, leading to a stronger, more durable slab. Remember, the right mix can make all the difference in your project's success!

Construction and Installation Techniques

When it comes to pouring reinforced concrete slabs, understanding the construction and installation techniques is crucial. The right method not only ensures structural integrity but also significantly impacts the project's timeline and overall costs. So, are you ready to get into the nitty-gritty of how to install your slabs efficiently? Let's explore!

In my experience at Concrete Slab Innovations, I’ve seen firsthand how essential it is to follow a systematic approach during installation. By adhering to best practices, contractors can avoid common pitfalls and deliver high-quality results. Here are some essential steps to keep in mind:

Essential Steps in Concrete Slab Installation

- Site Preparation: Clear the area and ensure a level subgrade.

- Formwork Installation: Set up the forms to shape the slab.

- Reinforcement Placement: Position steel rebar correctly to enhance strength.

- Concrete Pouring: Mix and pour concrete, ensuring consistent coverage.

- Finishing: Smooth the surface and apply any necessary treatments.

- Curing: Allow the concrete to cure properly for optimal strength.

Each of these steps plays a crucial role in ensuring your slab can handle the intended loads, reducing issues later on. Want to ensure your project runs smoothly? Following these steps is a surefire way to achieve that!

Common Construction Methods for Different Applications

Different projects may call for specific construction methods tailored to their unique needs. Whether you’re tackling residential foundations or large commercial structures, understanding these methods can lead to better outcomes. Let's dive into some common approaches:

- Traditional Slab Construction: Best for straightforward applications where minimal complexity is required.

- Post-Tensioned Slabs: Ideal for long spans, providing enhanced strength without additional weight.

- Slab on Grade: Common in residential projects, this involves pouring concrete directly on the ground.

- Elevated Slabs: Often used in commercial settings, these slabs are supported by beams or columns.

Each construction method brings its own set of benefits and challenges. It's vital to assess the specific needs of your project to select the best approach. As a contractor, are you familiar with how these methods can impact your work?

Flatwork Concrete Techniques

Flatwork refers to any concrete surface that is flat, such as sidewalks, driveways, and patios. Utilizing effective flatwork techniques not only enhances aesthetic appeal but also improves functionality. Methods like proper grading and finishing techniques can lead to lasting results. Have you considered how these techniques can elevate your projects?

Innovative Techniques for Enhanced Strength

As we push the boundaries of construction, innovative techniques like fiber-reinforced concrete are becoming more popular. This method integrates fibers into the concrete mix, providing additional strength and resistance to cracking. It’s amazing what a little innovation can do for slab durability, don’t you think?

Utilizing Precast Concrete for Efficient Construction

Precast concrete is another game-changer for construction speed and quality. Slabs can be manufactured off-site and installed quickly, reducing project time significantly. Plus, precast elements often come with enhanced quality control, ensuring that your projects meet the highest standards. Isn’t it time you explored this option to maximize efficiency?

Frequently Asked Questions about Reinforced Concrete Slabs

- What is the primary purpose of steel rebar in concrete slabs?

- Steel rebar is incorporated into concrete slabs to provide tensile strength, which plain concrete lacks. This allows the slab to withstand pulling forces and dynamic loads, preventing cracks and enhancing overall structural integrity.

- What are the main types of reinforced concrete slabs?

- The main types include one-way slabs (supported on two sides, carrying loads in one direction), two-way slabs (supported on all four sides, carrying loads in two directions), and flat slabs (two-way slabs directly supported by columns without beams).

- Why is proper curing essential for concrete slabs?

- Proper curing is crucial for concrete slabs to achieve optimal strength and durability. It involves maintaining adequate moisture and temperature conditions, which allows the concrete to hydrate effectively and reach its full design strength, reducing the likelihood of cracking and deterioration.

- What are some common construction methods for reinforced concrete slabs?

- Common methods include traditional slab construction for simple applications, post-tensioned slabs for long spans requiring enhanced strength, slab on grade for residential projects poured directly on the ground, and elevated slabs for commercial buildings supported by beams or columns.

- How do innovative techniques like fiber-reinforced concrete benefit slab construction?

- Fiber-reinforced concrete integrates fibers into the concrete mix, significantly enhancing its strength and resistance to cracking. This innovation improves the slab's durability and longevity, making it more resilient to various stresses and environmental conditions.

In conclusion, understanding the various construction and installation techniques for reinforced concrete slabs can transform your approach to building projects. By focusing on the right methods, you can ensure greater success and longevity in your slab installations. Are you ready to implement these techniques in your next project? Let's build something great together!

Recap of Key Points

- Reinforced concrete slabs provide essential structural support and durability for various construction projects.

- Understanding the types of slabs, such as one-way, two-way, and flat slabs, can help in selecting the right slab for specific needs.

- Choosing high-quality materials, including a suitable concrete mix and proper steel rebar placement, is crucial for optimal performance and longevity.

- Following essential steps in installation, from site preparation to curing, ensures structural integrity and efficiency.

- Different construction methods, like traditional, post-tensioned, and precast slabs, provide tailored solutions for various applications.

Popular Posts

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Consider this: the effective use of aluminum formwork can significantly streamline your construction

Consider this: the effective use of aluminum formwork can significantly streamline your construction

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a