Calculating Concrete Slab Loads

Have you ever wondered how critical load calculations are to the safety and durability of concrete slabs? Understanding these calculations can save you from costly mistakes and enhance your construction efficiency.

What You Will Learn

- The significance of accurate load calculations for ensuring structural safety and cost-effectiveness.

- Different types of loads, including dead loads, live loads, and point loads, and their unique considerations.

- Common misconceptions about load calculations that can lead to structural failures.

- The importance of compliance with design codes to enhance reliability and legal safety in construction.

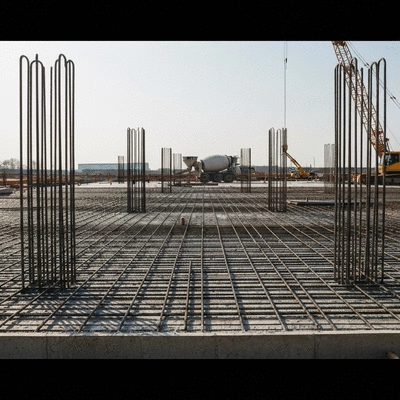

Concrete Slab Load Analysis: Key Load Types and Calculation Methods

This visual summarizes the critical load types impacting concrete slab design and the importance of compliance with design codes.

Types of Loads

- •Dead Loads: Slab self-weight, permanent fixtures (walls, finishes).

- •Live Loads: Occupants, furniture, equipment, vehicles (temporary).

- •Point Loads: Concentrated forces at specific areas (heavy machinery).

Importance of Compliance

- •Safety: Prevents structural failure, protects occupants.

- •Cost-effectiveness: Avoids over-engineering and costly repairs.

- •Quality Assurance: Adherence to ACI & ASCE guidelines ensures reliability.

Understanding Concrete Slab Load Calculation

When it comes to concrete slab construction, grasping the nuances of load calculation is crucial. Accurate load calculations are essential for ensuring the structural integrity and safety of any project. Have you ever considered how these calculations affect the lifespan of a slab? Understanding load calculations can help you avoid costly mistakes and enhance the efficiency of your construction processes.

As a seasoned professional in the field, I can tell you that the stakes are high. Inadequate calculations can lead to structural failures, which not only jeopardize the safety of occupants but also inflate project costs due to unforeseen repairs. That’s why it’s imperative to get these numbers right from the very start!

Importance of Accurate Load Calculations for Concrete Slabs

Accurate load calculations are vital for several reasons:

- Safety: Ensuring that a slab can support expected loads without risk of failure.

- Cost-effectiveness: Preventing over-engineering that leads to unnecessary material use and expense.

- Compliance with design codes that govern construction standards.

Each of these factors plays a critical role in project planning and execution. For instance, a well-calculated load can lead to efficient resource utilization, which ultimately impacts your project's bottom line positively.

Common Misconceptions About Slab Load Calculations

Many professionals, especially those new to the field, often harbor misconceptions about load calculations. Here are a few that I frequently encounter:

- “All loads are the same.” This couldn't be further from the truth! Different types of loads (dead, live, point) require unique considerations, as detailed in resources like the Wisconsin Department of Transportation's Bridge Manual, which outlines various load types for structural design.

- “Load calculations are a one-time task.” In reality, they should be revisited as project conditions evolve.

- “Software tools do all the work.” While they are helpful, understanding the underlying principles is crucial for accurate results.

By debunking these myths, we set a solid foundation for effective slab design and safety. Remember, awareness is the first step towards preventing potential pitfalls in construction!

Identifying the Types of Loads on Concrete Slabs

To ensure our slabs stand the test of time, we need to identify and understand the different types of loads they’ll encounter. This includes not only the weight of the slab itself but also everything it may support.

Several distinct types of loads must be considered in concrete slab design:

Defining Dead Load: Self-Weight and Finishes

The dead load refers to the weight of the slab itself, including all permanent fixtures such as finishes and equipment. Understanding this is crucial, as it forms the baseline for load calculations. Here are some components that contribute to dead loads:

- The weight of the concrete itself

- Supporting structures, such as beams

- Any additional finishes, like tiles or coatings

Each of these components adds to the overall weight supported by the slab, making accurate measurement essential for structural integrity. The California Department of Transportation provides comprehensive guidelines on loads and load combinations, emphasizing the importance of dead load considerations.

Exploring Live Load: Occupancy and Equipment Considerations

Next, we have the live load, which consists of temporary loads that change over time. This can include:

- People occupying the space

- Movable furniture and equipment

- Vehicles in parking structures

Understanding how these loads fluctuate is important for ensuring the slab can handle varying levels of stress during its lifespan. The USDA's Design Guide for Slabs-on-Ground offers further insights into live load considerations for concrete structures.

Understanding Point Loads on Slabs

Point loads refer to concentrated forces applied at specific points on the slab. These can arise from structural elements or equipment and significantly affect how the slab behaves under load.

Analysis of Concentrated Loads and Their Impacts

When concentrated loads are present, it’s vital to assess their impact on the surrounding areas of the slab. Over time, these concentrated forces can lead to cracking or other structural issues if not properly accounted for. This emphasizes the need for careful analysis during the design phase.

Evaluating Load Distribution Across Different Slab Types

How loads distribute across the slab can vary significantly based on its design. One-way vs. two-way slabs will handle loads differently, and recognizing these differences can lead to better design decisions. For example:

- One-way slabs: Typically designed to support loads in one direction, making them ideal for simple spans.

- Two-way slabs: Support loads in multiple directions, making them strong and suitable for larger spaces.

By understanding these dynamics, we can optimize our designs for better performance and longevity.

Detailed Steps for Concrete Slab Load Calculation

Once we’ve identified the types of loads, it’s time to delve into the methods for calculating them accurately. This is where our knowledge as industry professionals can truly shine!

Engage with Us!

As you navigate through the complexities of concrete slab load calculations, we want to know: What aspect do you find most challenging?

Frequently Asked Questions About Concrete Slab Load Calculations

- Q: Why are accurate load calculations important for concrete slabs?

- A: Accurate load calculations are crucial for ensuring the structural integrity and safety of a project, preventing costly errors, and enhancing construction efficiency. They help avoid structural failures, protect occupants, and prevent over-engineering.

- Q: What are the main types of loads considered in concrete slab design?

- A: The three primary types of loads are dead loads (self-weight of the slab and permanent fixtures), live loads (temporary loads like people, furniture, and vehicles), and point loads (concentrated forces at specific areas).

- Q: What are some common misconceptions about load calculations?

- A: Common misconceptions include believing that all loads are the same, that load calculations are a one-time task, and that software tools do all the work. Each type of load requires unique consideration, calculations should be revisited as projects evolve, and understanding underlying principles is vital even with software tools.

- Q: How do dead loads differ from live loads?

- A: Dead loads are static and permanent, encompassing the weight of the slab itself and fixed elements like walls and finishes. Live loads are temporary and variable, including the weight of people, movable furniture, equipment, and vehicles.

- Q: Why is compliance with design codes important?

- A: Compliance with design codes, such as those from the ACI (American Concrete Institute) and ASCE (American Society of Civil Engineers), ensures quality assurance, provides legal safety for contractors and engineers, and leads to improved performance and durability of concrete slabs.

Key Takeaways for Concrete Slab Load Calculation

Understanding concrete slab load calculation is crucial for ensuring the safety and longevity of any construction project. In this section, we will recap the various types of loads and the methods employed to calculate them. With accurate load calculations, we can prevent structural failures and enhance the overall performance of concrete slabs.

Recap of Load Types and Calculation Methods

There are primarily three types of loads that we encounter in concrete slab design: dead loads, live loads, and point loads. Each plays a significant role in determining how a slab performs under various conditions. Let’s summarize these:

- Dead Loads: These are static forces that include the weight of the slab itself, as well as any fixed elements like walls and roofing.

- Live Loads: These refer to temporary or movable loads such as people, furniture, and equipment that occupy the space.

- Point Loads: Concentrated forces that act on a specific area of the slab, such as heavy machinery or large objects.

Utilizing the right methods for calculating these loads is vital. For instance, dead loads are often calculated by determining the self-weight of the materials used, while live loads have standardized values based on building codes. Understanding these fundamentals ensures that contractors and engineers can create safe and effective designs.

Importance of Compliance with Design Codes

Adhering to design codes is not just a regulatory requirement but a fundamental aspect of maintaining safety standards in our industry. Compliance with guidelines such as the ACI (American Concrete Institute) and ASCE (American Society of Civil Engineers) helps ensure that structures can support the expected loads over their lifespan.

- Quality Assurance: Design codes are developed based on extensive research and practical experience, providing a framework that enhances the reliability of concrete slabs.

- Legal Safety: Following these codes protects contractors and engineers from liability issues related to structural failures.

- Improved Performance: Compliance leads to designs that are optimized for load-bearing capacity and durability.

At Concrete Slab Innovations, we emphasize the importance of staying informed about the latest updates in design codes to ensure that your projects meet all necessary standards.

Implications of Construction Safety and Quality Control in Slab Design

Safety is paramount in the construction industry, and it begins with sound design practices. Proper load calculations directly influence the quality control processes throughout construction. Here are a few key considerations:

- Site Inspections: Regular checks during construction can help identify potential issues related to load-bearing integrity.

- Material Quality: Using high-quality materials for slabs contributes to their performance under load.

- Worker Training: Ensuring that your team is well-versed in safety protocols can prevent accidents and promote a culture of quality.

Incorporating comprehensive safety measures in your planning and execution phases helps mitigate risks, ultimately leading to successful project outcomes. Remember, when we prioritize safety and quality, we also enhance our reputation in the industry!

Engaging Tools and Resources for Further Learning

As we continue to advance in the field of concrete slab construction, it's essential to leverage available tools and resources that enhance our understanding of load calculations. Below, I’ll outline some key resources that I find invaluable.

Interactive Load Calculation Tools and Calculators

Utilizing technology can streamline the load calculation process significantly. Tools such as online calculators allow for quick assessments of various load scenarios. They can save you both time and effort, enabling you to focus on other critical aspects of your projects.

- LoadCalc Pro: A user-friendly tool designed for quick load assessments.

- BeamCalc: Ideal for calculating loads across beams and slabs simultaneously.

- Concrete Load Calculator: Specifically tailored for concrete applications, it provides accurate readings based on user input.

These tools are essential for modern construction professionals looking to enhance their efficiency and precision in load calculations!

Visual Guides and Diagrams for Enhanced Understanding

Visual aids can greatly improve comprehension of complex concepts. Diagrams illustrating load distribution, slab types, and reinforcement layouts provide a clear reference for your calculations.

Consider creating a dedicated folder for these resources, allowing your team to access them easily during planning and execution phases. Visual materials can serve as powerful training tools for new employees as well!

Suggested Readings and Video Tutorials for Practical Applications

Staying updated with industry literature is vital. I recommend checking out some of the following resources:

- “Design of Concrete Structures” by Martin B. Williams: This comprehensive guide covers everything from basic principles to advanced design techniques.

- YouTube Tutorials: Channels like Civil Engineering Academy offer a wealth of practical examples and explanations regarding load calculations.

- Industry Webinars: Participating in webinars can provide insights into the latest technologies and best practices in slab design.

Engaging with these resources not only broadens your knowledge but also keeps you connected with the latest innovations in our field!

Exploring Design Software: CAD and BIM in Structural Engineering

Adopting software tools like CAD (Computer-Aided Design) and BIM (Building Information Modeling) can revolutionize the way we approach slab design. These platforms allow for detailed modeling that considers load distribution and structural integrity.

- AutoCAD: A staple in architectural design that can streamline the drafting of slab layouts.

- Revit: Offers advanced capabilities for BIM, allowing for collaborative design efforts and real-time updates.

- Tekla Structures: Specialized software for concrete detailing, which enhances accuracy in load calculations.

By utilizing these advanced tools, we can ensure that our designs are not only efficient but also compliant with the latest industry standards. Are you ready to take your slab design process to the next level?

Recap of Key Points

Here is a quick recap of the important points discussed in the article:

- Accurate Load Calculations: Essential for ensuring safety, cost-effectiveness, and compliance with design codes.

- Types of Loads: Understand the three main types of loads: dead loads, live loads, and point loads, and their implications on slab design.

- Common Misconceptions: Be aware that not all loads are the same, and load calculations should not be a one-time task.

- Importance of Compliance: Adhering to design codes ensures safety and enhances the structural performance of slabs.

- Quality Control: Regular site inspections, high-quality materials, and worker training are vital for maintaining safety and quality during construction.

Popular Posts

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Consider this: the effective use of aluminum formwork can significantly streamline your construction

Consider this: the effective use of aluminum formwork can significantly streamline your construction

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a