Understanding Commercial Concrete Slab Thickness

Have you ever considered how the thickness of a concrete slab can influence not just its durability but also the safety and longevity of a structure? This critical aspect often determines the success of construction projects, especially in commercial settings. Let’s explore some essential insights that will empower your decision-making.

What You Will Learn

- Correct slab thickness is essential for structural integrity and longevity.

- Thickness recommendations vary: 4-6 inches for light-duty applications, 6-8 inches for medium-duty, and 8-12 inches for heavy-duty.

- Local building codes significantly influence slab thickness requirements.

- Proper load analysis can prevent costly repairs and enhance safety.

- Reinforcement techniques like fiber mesh and rebar are crucial for durability in high-load scenarios.

- Site assessments are necessary to determine the appropriate thickness based on soil and environmental conditions.

Recommended Commercial Concrete Slab Thicknesses

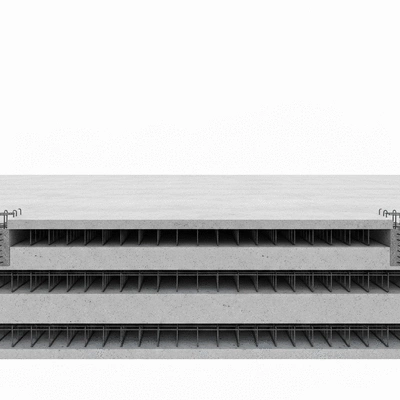

This visual summarizes the recommended thickness ranges for commercial concrete slabs across various applications, from light-duty to heavy-duty scenarios.

Light Duty Applications

For pedestrian traffic and occasional furniture loads.

Medium Duty Scenarios

Suitable for retail spaces and light warehouses with consistent traffic.

Heavy Duty Requirements

For high-traffic industrial applications like loading docks and warehouses.

Key Considerations for Thickness

- Load-bearing needs & traffic type

- Building codes & regional variations

- Soil type & environmental factors

- Reinforcement (fiber mesh, rebar)

- Concrete strength (PSI)

Understanding Commercial Concrete Slab Thickness Requirements

When it comes to commercial concrete slabs, understanding thickness requirements is vital. The correct slab thickness not only influences structural integrity but also affects the longevity and performance of the slab itself. Choosing the right thickness is not just about meeting standards but also ensuring the slab can withstand its intended use.

Many factors contribute to the decision-making process regarding slab thickness. From expected loads to environmental conditions, every project is unique. In my experience at Concrete Slab Innovations, I’ve seen how these considerations can directly impact the success of a project. Whether you're dealing with light pedestrian traffic or heavy industrial equipment, getting this right can save time and money.

Why Thickness Matters in Commercial Concrete Slabs

The thickness of a concrete slab plays a critical role in its overall functionality and durability. For each specific application, a tailored approach to thickness is necessary to ensure that the slab can support the expected load without cracking or failing. Here's why it matters:

- Load Support: Thicker slabs can handle greater loads, making them essential for heavy-duty applications.

- Longevity: More thickness often equates to longer lifespan and durability against wear and tear.

- Cost Efficiency: Investing in the right thickness upfront can prevent costly repairs and replacements down the line.

In essence, the right thickness enhances not only the performance of the concrete but also the safety of the structure. It’s crucial to assess the specific needs based on what the slab will be exposed to throughout its life.

Recommended Thickness Ranges for Various Applications

Light Duty Applications: Thickness Insights

For light traffic areas such as sidewalks and patios, the recommended thickness typically ranges from 4 to 6 inches. This thickness provides adequate support while being cost-effective for less demanding environments.

- Sidewalks: 4 inches is sufficient for pedestrian traffic.

- Patios: 5 to 6 inches ensures durability against occasional furniture loads.

- Driveways: If light vehicles are involved, aim for the higher end of the range.

Choosing the appropriate thickness for these applications not only supports everyday use but also helps in maintaining aesthetic appeal over time. At Concrete Slab Innovations, we always emphasize that even light-duty slabs deserve careful planning.

Medium Duty Scenarios: Choosing the Right Thickness

For medium-duty scenarios like retail spaces and light warehouses, a thickness of 6 to 8 inches is ideal. This range balances strength and cost, making it suitable for spaces that experience more consistent traffic.

- Retail Spaces: 6 inches allows for the weight of merchandise and foot traffic.

- Light Warehouses: 7 to 8 inches can accommodate light machinery and storage racks.

- Parking Lots: If designated for light vehicles, 7 inches will ensure adequate support.

In my experience, opting for the right thickness in these scenarios not only enhances durability but also boosts overall project efficiency. When you get it right, you create a foundation for a successful investment.

Heavy Duty Requirements: Optimizing for Load and Use

For high-traffic industrial applications, such as loading docks and warehouses, slab thickness should ideally range from 8 to 12 inches or more. This substantial thickness is essential to support heavy loads and rigorous use.

- Loading Docks: Slabs should be at least 10 inches thick to withstand forklift and truck traffic.

- Industrial Warehouses: Aim for 12 inches or more to ensure safety and longevity.

- Heavy Equipment Zones: Consider additional reinforcement based on specific equipment weights.

It's clear that as the demands on the slab increase, so too must its thickness. At Concrete Slab Innovations, we always recommend consulting with a professional to assess your unique requirements, ensuring that your project is built on a strong foundation.

Load and Use Considerations Affecting Slab Thickness

Analyzing Load-Bearing Needs

Understanding the load-bearing needs of your concrete slab is essential when determining the appropriate thickness. Factors such as the type of traffic and equipment used can heavily influence your decisions. For example, higher load requirements necessitate thicker slabs to prevent cracking and other structural failures. For more comprehensive guidelines on pavement design and load analysis, you can refer to resources like the FHWA Publication on Pavement Design.

In my experience, analyzing these needs through careful calculation can lead to significant benefits, including:

- Improved Safety: Reducing the risk of slab failure and workplace accidents.

- Cost Savings: Investing in proper thickness now can save you from future repairs.

- Increased Efficiency: Ensuring that your slab meets its intended use enhances project timelines.

Building Codes and Compliance Factors

Local building codes play a crucial role in determining slab thickness for commercial applications. These regulations are designed to ensure safety and structural integrity, and they vary based on region and the specific usage of the slab. For instance, New York City has specific administrative codes that dictate construction requirements, which can be reviewed in the New York City Administrative Code.

It's essential to be aware of these codes during your planning stages to avoid costly delays or compliance issues. At Concrete Slab Innovations, we always advocate for thorough research into local regulations to ensure your project meets all necessary standards.

Site Assessment for Optimal Thickness Decisions

The importance of site assessment cannot be overstated when it comes to determining the right slab thickness. Factors such as soil type, drainage, and environmental conditions significantly influence the required thickness. Detailed guidelines for floor slabs in various facilities, including considerations for site conditions, can be found in resources like the WBDG Unified Facilities Criteria (UFC) for Floor Slabs.

- Soil Quality: Poor soil conditions may necessitate thicker slabs or additional support.

- Drainage Requirements: Proper drainage design can affect the integrity of the slab over time.

- Environmental Factors: Weather conditions can also dictate material choices and slab thickness.

Conducting a detailed site assessment helps to ensure that the chosen slab thickness supports its intended use effectively. My emphasis on this process stems from seeing firsthand the positive outcomes it can yield for projects.

Reinforcement Techniques to Enhance Concrete Durability

The Role of Fiber Mesh and Rebar in Slab Strength

To maximize the performance and lifespan of concrete slabs, employing reinforcement techniques such as fiber mesh and rebar is essential. These materials enhance the slab's ability to withstand stress and cracking.

- Fiber Mesh: Provides uniform support throughout the slab, improving resistance to cracking.

- Rebar: Offers increased tensile strength, essential for heavy-duty applications.

- Composite Reinforcements: New technologies are being developed that offer advanced durability and performance.

Incorporating these reinforcement methods can greatly affect the slab's durability, making it a wise investment in the long run. At Concrete Slab Innovations, we stay updated on the latest advancements in these materials to provide the best advice to our clients.

Concrete Strength Ratings: What You Need to Know

Understanding concrete strength ratings, often measured in psi (pounds per square inch), is crucial when considering slab thickness. The higher the psi rating, the stronger and more durable the concrete will be, allowing for thinner slabs in some applications.

- Standard Strength: A typical commercial slab might use concrete rated at 3,000 to 4,000 psi.

- Heavy-Duty Applications: Consider concrete with a strength rating of 5,000 psi or more for industrial use.

- Special Mixes: Innovations in concrete mixes can enhance performance beyond traditional ratings.

By understanding these ratings, you can make informed decisions about slab thickness and overall project specifications. Concrete Slab Innovations is here to help you navigate these choices effectively!

Innovations in Concrete Mix for Enhanced Performance

The field of concrete technology has seen numerous advancements that improve the performance of slabs. Innovations in concrete mix designs can significantly enhance durability, resistance to wear, and longevity.

- High-Performance Concrete: This mix offers enhanced strength and durability for demanding applications.

- Self-Consolidating Concrete: Ensures better flow and eliminates voids, leading to higher structural integrity.

- Sustainable Mixes: Using recycled materials can lead to lower environmental impact without compromising strength.

Exploring these innovative materials can lead to better outcomes in your construction projects. At Concrete Slab Innovations, we actively seek out and share the latest trends to keep our clients at the forefront of industry standards.

Comparing Commercial and Residential Slab Thickness

Key Differences in Design and Application

Commercial slabs typically require thicker designs compared to residential slabs due to the different load and usage patterns. These differences stem from the intended use, which can significantly impact the required thickness.

- Load Capacity: Commercial slabs often bear heavier loads due to equipment and vehicular traffic.

- Durability Needs: Commercial spaces need slabs that can withstand more wear and tear over time.

- Regulatory Standards: Stricter building codes apply to commercial structures, necessitating more robust designs.

Understanding these differences helps in making educated choices regarding thickness and design for each type of project. My experience has shown that careful planning is key in achieving success in both commercial and residential applications.

Application-Specific Thickness Considerations

Each application has its unique requirements that dictate slab thickness. For instance, commercial driveways, warehouses, and retail spaces each have specific needs based on traffic and load patterns.

- Commercial Driveways: Generally require thicker slabs (6-8 inches) to support delivery trucks.

- Warehouse Floors: May need substantial thickness (8-12 inches) to accommodate heavy machinery.

- Retail Space Floors: Often are in the 6-8 inch range, balancing load support and cost.

By tailoring thickness to the application, you ensure your slab is not only functional but also cost-effective. At Concrete Slab Innovations, we frequently share insights on how to align your design with application needs to optimize performance.

FAQs on Commercial Concrete Slab Thickness

Here are some frequently asked questions to help clarify key aspects of commercial concrete slab thickness:

What is the recommended concrete slab thickness for light-duty commercial applications?

For light-duty applications such as sidewalks and patios, a thickness of 4 to 6 inches is generally recommended. This is sufficient for pedestrian traffic and occasional light loads.

How thick should a concrete slab be for medium-duty commercial use, like retail stores?

For medium-duty scenarios including retail spaces and light warehouses, a thickness of 6 to 8 inches is ideal. This accommodates consistent foot traffic and light machinery.

What thickness is required for heavy-duty commercial applications such as loading docks?

Heavy-duty applications like loading docks and industrial warehouses typically require a slab thickness of 8 to 12 inches or more to withstand heavy loads and rigorous use, including forklift and truck traffic.

Why are building codes important when determining slab thickness?

Local building codes are crucial as they specify minimum thickness requirements based on regional climate, soil conditions, and the intended use of the slab. Adhering to these codes ensures safety, structural integrity, and avoids costly compliance issues.

How do reinforcement techniques like fiber mesh and rebar enhance concrete durability?

Fiber mesh provides uniform support, reducing cracking, while rebar offers increased tensile strength, essential for heavy loads. Both significantly improve the slab's ability to withstand stress and extend its lifespan.

Does concrete strength (PSI) affect slab thickness?

Yes, the concrete strength rating (PSI) directly impacts slab thickness. Higher PSI concrete is stronger and more durable, sometimes allowing for a slightly thinner slab while maintaining structural integrity, especially for heavy-duty applications.

Addressing Content Gaps in Slab Thickness Knowledge

Regional Code Variations: What to Consider

Regional code variations play a significant role in slab thickness requirements. Different areas may have specific regulations based on climate, soil conditions, and historical data regarding structural integrity.

- Local Codes: It's crucial to be familiar with local building codes to ensure compliance.

- Climate Considerations: Areas prone to extreme weather may require thicker slabs.

- Soil Testing: Understanding soil properties can impact your design choices and necessary thickness.

Being aware of these factors can prevent errors in planning and execution, ensuring that your project adheres to all necessary guidelines. Consulting with experts, like us at Concrete Slab Innovations, can streamline this process!

Cost Implications of Thickness Choices

The choice of slab thickness directly impacts project costs. Thicker slabs may require more materials and labor, while thinner slabs can lead to savings but may not be suitable for all applications.

- Initial Costs: Thicker slabs typically have higher upfront costs due to more material and reinforcement.

- Long-Term Savings: Investing in the appropriate thickness can reduce maintenance and repair costs over time.

- Overall Value: Balancing thickness with the right materials can result in better ROI on your project.

A thorough understanding of these implications can help you make informed decisions that align with both your budget and project goals. We at Concrete Slab Innovations are here to help you navigate these financial considerations effectively!

Installation Best Practices for Optimal Performance

To achieve optimal slab performance, it's critical to follow best practices during installation. Factors like curing times and environmental conditions can greatly influence the quality of the finished product.

- Proper Curing: Ensuring adequate curing times improves strength and durability.

- Weather Considerations: Installing in ideal weather conditions can affect the curing process.

- Site Preparation: Thorough grading and compaction of the site can enhance slab performance.

By adhering to these best practices, you set your project up for success from the start. At Concrete Slab Innovations, we advocate for meticulous planning to ensure that installation goes smoothly and results in the best possible outcome.

Concrete Finishing Techniques for Enhanced Durability

Concrete finishing techniques significantly affect the durability and appearance of the slab. Employing the right finishing methods can enhance resistance to wear and weathering.

- Smoothing Techniques: Ensuring a smooth finish reduces wear and increases longevity.

- Sealing: Applying sealers can protect against moisture and chemical damage.

- Texturing: Adding texture can improve slip resistance, especially in high-traffic areas.

These finishing touches can lead to a more resilient slab that stands up to the rigors of its intended use. At Concrete Slab Innovations, we’re always happy to share the latest techniques to help you achieve the best results!

Innovative Materials and Technologies Enhancing Slab Performance

Innovations in materials and technologies continue to propel the concrete industry forward. New solutions are emerging that improve not only the strength of slabs but also their sustainability and performance.

- Recycled Materials: Incorporating recycled aggregates can reduce environmental impact.

- High-Performance Blends: Advanced mixes can enhance strength and resistance to cracking.

- Smart Technologies: Integrating sensors in concrete can monitor health and performance over time.

Staying informed about these advancements can give your projects a competitive edge. At Concrete Slab Innovations, we strive to keep our clients updated on the latest trends and technologies shaping the future of concrete construction.

Pro Tip

When selecting the thickness for your concrete slab, consider not only the immediate load requirements but also future potential uses of the space. For example, if there's a chance that a light-duty area might later support heavier traffic or machinery, opting for a slightly thicker slab can save you from costly modifications later on.

Summarizing Key Takeaways on Concrete Slab Thickness

When it comes to selecting the right thickness for commercial concrete slabs, several key factors come into play. Understanding the specific requirements for each application—whether it's light, medium, or heavy-duty—is crucial for achieving optimal performance and safety. Here’s a quick recap of the recommended thickness ranges:

- Light Duty Applications: 4-6 inches for areas like sidewalks and patios.

- Medium Duty Scenarios: 6-8 inches for retail spaces and light warehouses.

- Heavy Duty Requirements: 8-12+ inches for high-traffic areas such as loading docks and warehouses.

These thickness recommendations are grounded in the expected load and usage patterns, ensuring that your slabs are not only safe but also durable enough to withstand daily operations.

Making Informed Decisions for Your Commercial Concrete Needs

As we wrap up our discussion on concrete slab thickness, it's important to consider all the factors we've covered. From load-bearing needs to local building codes, every element plays a crucial role in your decision-making process. Are you ready to take the next step in your concrete project? Remember, choosing the right thickness is essential for maximizing both performance and safety.

At Concrete Slab Innovations, we are here to help you navigate these choices with ease. Don’t hesitate to reach out for expert consultation or more information on selecting the right concrete solutions for your projects. Together, we can ensure that your slabs meet the highest standards of quality and efficiency!

Recap of Key Points

Here is a quick recap of the important points discussed in the article:

- Thickness Matters: The correct slab thickness affects structural integrity, longevity, and cost efficiency.

- Recommended Thickness: Light-duty applications require 4-6 inches, medium-duty 6-8 inches, and heavy-duty can go from 8-12+ inches.

- Load-Bearing Needs: Analyze load requirements to prevent cracking and ensure safety.

- Local Codes: Always consider regional building codes and site assessments for optimal thickness decisions.

- Reinforcement Techniques: Employ fiber mesh and rebar to enhance slab durability and performance.

- Installation Best Practices: Focus on proper curing, weather conditions, and site preparation for best results.

Popular Posts

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Consider this: the effective use of aluminum formwork can significantly streamline your construction

Consider this: the effective use of aluminum formwork can significantly streamline your construction

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a