Project Scale

Understanding Reinforced Industrial Slabs

As the construction industry evolves, understanding the materials and methods that enhance durability and efficiency is paramount. One of the standout solutions in modern concrete construction is the reinforced industrial slab, designed to withstand the rigors of industrial environments. Let's explore the critical insights that can bolster your construction projects.

What You Will Learn

- Reinforced industrial slabs incorporate materials like steel rebar and fibers to enhance structural integrity and load-bearing capacity.

- These slabs offer increased load capacity, making them ideal for heavy machinery and industrial applications.

- Choosing the right reinforcement, such as Steel Fiber Reinforced Concrete (SFRC), can lead to significant long-term cost savings and reduced maintenance.

- Understanding compliance with local building codes and safety standards is essential for ensuring the success and integrity of your project.

Reinforced Industrial Slabs: SFRC vs. Traditional Reinforcement

This comparison highlights key considerations when choosing between Steel Fiber Reinforced Concrete (SFRC) and traditional reinforcement methods for industrial slabs.

Steel Fiber Reinforced Concrete (SFRC)

- Enhanced Flexural Strength: Improves resistance to bending.

- Reduced Cracking: Fibers distribute stress evenly.

- Lower Material Costs: Reduces need for traditional rebar.

- Faster Construction Times: Quick placement and curing.

Traditional Reinforcement

- Rebar Reinforcement: Steel rebar for tensile strength.

- Established Method: Widely understood and implemented.

- Predictable Performance: Extensive historical data.

- Material Availability: Easily sourced globally.

Key Decision Factors

Load Requirements

Construction Timeline

Budget Constraints

Understanding Reinforced Industrial Slabs: Definitions and Importance

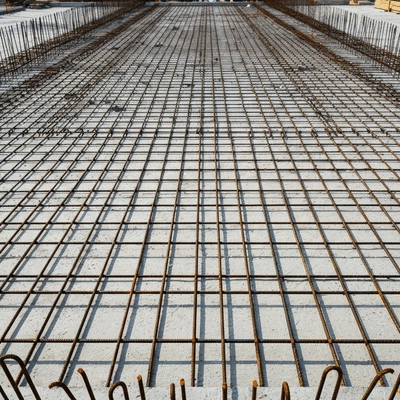

When it comes to concrete slab construction, understanding what a reinforced industrial slab is can make all the difference in your project. These slabs are designed with additional materials, such as steel rebar or fibers, to enhance their structural integrity and load-bearing capabilities. This reinforcement is essential for industrial applications where heavy machinery and dynamic loads are common.

Incorporating reinforced slabs into your project not only boosts durability but also ensures greater performance efficiency. At Concrete Slab Innovations, we prioritize educating our clients about these systems to help them make informed decisions for their construction needs. For further detailed information, you can refer to resources like the FHWA's guidelines on concrete pavement and materials.

What Is a Reinforced Industrial Slab?

A reinforced industrial slab is a flat concrete surface that has been enhanced with embedded steel or synthetic fibers. These materials provide extra strength, making the slab capable of withstanding heavier loads than standard concrete slabs alone. The use of reinforcement is vital in settings such as warehouses, factories, and other industrial environments where durability is key.

- Rebar Reinforcement: Traditional steel rebar is placed in a grid pattern to provide tensile strength.

- Steel Fiber Reinforcement: Steel fibers mixed into the concrete enhance crack resistance and improve load distribution.

- Composite Reinforcement: Advanced materials that combine different substances to optimize performance.

Understanding these components helps in selecting the right type of reinforcement for your specific project requirements. As an industry expert, I often emphasize that the right choice can lead to significant cost savings and enhanced structural integrity. For comprehensive guidance on structural practices, the WBDG offers valuable insights on floor slabs for facilities, including material selection.

Key Benefits of Using Reinforced Industrial Slabs

Reinforced industrial slabs offer various advantages that can elevate your construction project. Here are some of the key benefits:

- Increased Load Capacity: These slabs can handle heavier weights, making them suitable for industrial environments.

- Crack Resistance: Reinforcement minimizes the risk of cracks forming over time, preserving the slab's integrity.

- Longevity: With proper installation, reinforced slabs can last for decades, reducing the need for repairs.

Choosing reinforced slabs means investing in a solution that not only meets current demands but also adapts to future needs. As I’ve seen firsthand in my experience, the long-term benefits significantly outweigh the initial costs, making it a wise choice for contractors and project managers alike.

Durability and Load-Bearing Capacity of Reinforced Industrial Slabs

The durability of reinforced industrial slabs comes from their enhanced load-bearing capacity. This means they can support heavy machinery, equipment, and materials without compromising structural integrity. I've often worked with clients who are amazed at the performance of these slabs when properly engineered. For more on the behavior of concrete structures, the ACI provides detailed standards and guides for the design and construction of concrete structures.

- High Load-Bearing Capacity: Reinforced slabs can support dynamic loads, making them ideal for industrial applications.

- Resistance to Environmental Factors: These slabs resist moisture, temperature changes, and chemical exposure, ensuring longevity.

- Reduced Maintenance Needs: With their robust design, reinforced slabs require less upkeep compared to conventional options.

Incorporating reinforced slabs into your design not only enhances safety but also improves overall project efficiency. As a construction professional, I can attest to the profound impact that these slabs have on project timelines and cost management.

Pro Tip

To maximize the benefits of your reinforced industrial slabs, consider conducting a thorough analysis of your project’s specific load requirements. Tailoring your reinforcement strategy, whether through traditional rebar or innovative steel fiber solutions, can lead to enhanced durability and cost-effectiveness. Remember, investing time in the planning phase can yield significant long-term savings and performance improvements!

Summarizing the Value of Reinforced Industrial Slabs

When it comes to building durable and efficient structures, reinforced industrial slabs stand out as a top choice. Their unique combination of strength and versatility makes them ideal for a variety of applications. At Concrete Slab Innovations, we believe that understanding the benefits of these slabs can lead to smarter construction decisions!

One of the most effective options out there is Steel Fiber Reinforced Concrete (SFRC). Choosing SFRC for your next project can significantly enhance its structural integrity while also optimizing costs. Imagine being able to combine cost savings with superior performance—what a winning combination!

Why Choose Steel Fiber Reinforced Concrete for Your Next Project?

Steel Fiber Reinforced Concrete offers several advantages that traditional reinforcement methods simply can't match. Here’s a quick look at some of the standout benefits:

- Enhanced Flexural Strength: SFRC improves the slab’s resistance to bending and deformation.

- Reduced Cracking: The fibers help distribute stress evenly, minimizing the likelihood of cracks.

- Lower Material Costs: Using SFRC can reduce the overall need for traditional reinforcement materials.

- Faster Construction Times: Quick placement and curing can lead to significant time savings on the job site.

These factors are essential for ensuring a successful and efficient construction process, making SFRC a smart choice for any project.

Evaluating Your Options: When to Use SFRC vs. Traditional Reinforcement

Choosing between SFRC and traditional reinforcement methods doesn’t have to be daunting. Here are some key considerations to help you make the best decision:

- Project Scale: For larger projects, SFRC often proves more cost-effective due to its reduced material needs.

- Load Requirements: If the slab will bear significant loads, SFRC’s enhanced durability might be the way to go.

- Construction Timeline: Projects under tight deadlines may benefit from the faster installation associated with SFRC.

- Budget Constraints: If your budget allows for innovative solutions, investing in SFRC pays off in long-term durability.

By weighing these factors, you can confidently choose the right reinforcement method that aligns with your project's specific needs. Are you ready to take the plunge into steel fiber reinforced concrete? Let’s elevate your next project together!

Next Steps for Implementing Reinforced Slabs

Now that you understand the value that reinforced industrial slabs bring to your projects, it’s time to take action. Implementing these insights can lead to tangible improvements in your construction outcomes. Let’s explore how you can proceed effectively!

Accessing Technical Resources and Guidelines

To ensure the successful application of reinforced slabs, having the right resources is crucial. Here are some excellent starting points:

- Industry Standards: Familiarize yourself with guidelines from organizations like ACI (American Concrete Institute).

- Technical Documentation: Review concrete specifications and installation manuals from suppliers.

- Workshops and Webinars: Participate in events hosted by industry experts to expand your knowledge.

These resources will equip you with the information needed to make informed decisions throughout your project.

Engaging with Suppliers and Contractors for Your Project Needs

Building strong relationships with suppliers and contractors is key to your project's success. Here are some steps to engage effectively:

- Research Suppliers: Look for suppliers who specialize in SFRC and have a proven track record.

- Request Quotes: Obtain quotes from multiple contractors to compare services and pricing.

- Schedule Consultations: Discuss your specific needs and understand each contractor’s approach.

With the right partners on your side, you can navigate the construction process more smoothly!

Understanding Building Codes and Regulations in Reinforced Slab Design

Finally, compliance with local building codes and regulations is essential. Here are some key areas to focus on:

- Local Regulations: Ensure your project meets all local zoning and construction regulations.

- Safety Standards: Adhere to safety standards to protect your workers and project integrity.

- Documentation: Keep thorough documentation for all processes to facilitate inspections and approvals.

This diligence not only promotes safety but also fosters trust with stakeholders involved in your project. Ready to start your journey with reinforced slabs? Let’s make your next construction project a success!

Recap of Key Points

Here is a quick recap of the important points discussed in the article:

- Understanding Reinforced Industrial Slabs: These slabs enhance structural integrity through materials like steel rebar and fibers, making them crucial for heavy load environments.

- Key Benefits: Reinforced slabs provide increased load capacity, crack resistance, and longevity, proving essential for industrial applications.

- Types of Reinforcement: Options include rebar, steel fiber, and composite reinforcement for tailored project needs.

- Choosing the Right Method: Consider project scale, load requirements, and budget constraints when deciding between Steel Fiber Reinforced Concrete (SFRC) and traditional methods.

- Next Steps: Utilize technical resources, engage with suppliers, and understand building codes to successfully implement reinforced slabs in your projects.

Frequently Asked Questions about Reinforced Industrial Slabs

- What is a reinforced industrial slab?

- A reinforced industrial slab is a concrete surface enhanced with additional materials like steel rebar or fibers to boost its structural integrity and load-bearing capacity, making it suitable for heavy industrial use.

- What are the main benefits of using reinforced industrial slabs?

- Key benefits include increased load capacity for heavy machinery, enhanced crack resistance to preserve slab integrity, and greater longevity, reducing the need for frequent repairs.

- How does Steel Fiber Reinforced Concrete (SFRC) compare to traditional reinforcement?

- SFRC offers enhanced flexural strength, reduced cracking, potentially lower material costs, and faster construction times compared to traditional rebar reinforcement, which relies on a well-established method with predictable performance and readily available materials.

- What factors should be considered when choosing a reinforcement method?

- When choosing between SFRC and traditional reinforcement, consider the project scale, specific load requirements, construction timeline, and budget constraints to determine the most suitable option.

- Where can I find technical resources and guidelines for reinforced slabs?

- You can access technical resources from organizations like the American Concrete Institute (ACI), review technical documentation from suppliers, and participate in industry workshops and webinars to stay informed.

Popular Posts

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Consider this: the effective use of aluminum formwork can significantly streamline your construction

Consider this: the effective use of aluminum formwork can significantly streamline your construction

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a