Understanding Waffle Slab Concrete

Have you ever considered how an innovative building solution could redefine your construction projects? Waffle slab concrete is a game changer in modern architecture, combining efficiency with structural integrity.

What You Will Learn

- Waffle slab concrete features a grid-like structure that reduces weight while enhancing load-bearing capacity.

- Understanding the differences between waffle slabs and waffle pod slabs can lead to more informed construction choices.

- Reinforced concrete is key to the performance of waffle slabs, improving strength, flexibility, and safety.

- Key factors such as soil conditions, span requirements, and budget constraints are essential in determining the suitability of waffle slabs for your project.

Waffle Slab Suitability: Key Decision Criteria & Installation Workflow

This visual outlines the crucial factors for determining if waffle slabs are right for your project and the step-by-step process for their installation.

Key Decision Criteria for Waffle Slabs

Perform best in stable soils, crucial for unique design.

Ideal for larger spans and open spaces due to load distribution.

Higher upfront costs, but often justified by long-term benefits.

Waffle Slab Installation Workflow

- Site Preparation: Clear and level site for stable foundation.

- Formwork Setup: Install aluminum forms to create waffle pattern.

- Reinforcement Placement: Position steel bars for added strength.

- Concrete Pouring: Evenly pour concrete mixture into forms.

- Curing Process: Allow proper curing for optimal strength.

Understanding Waffle Slab Concrete: An Overview

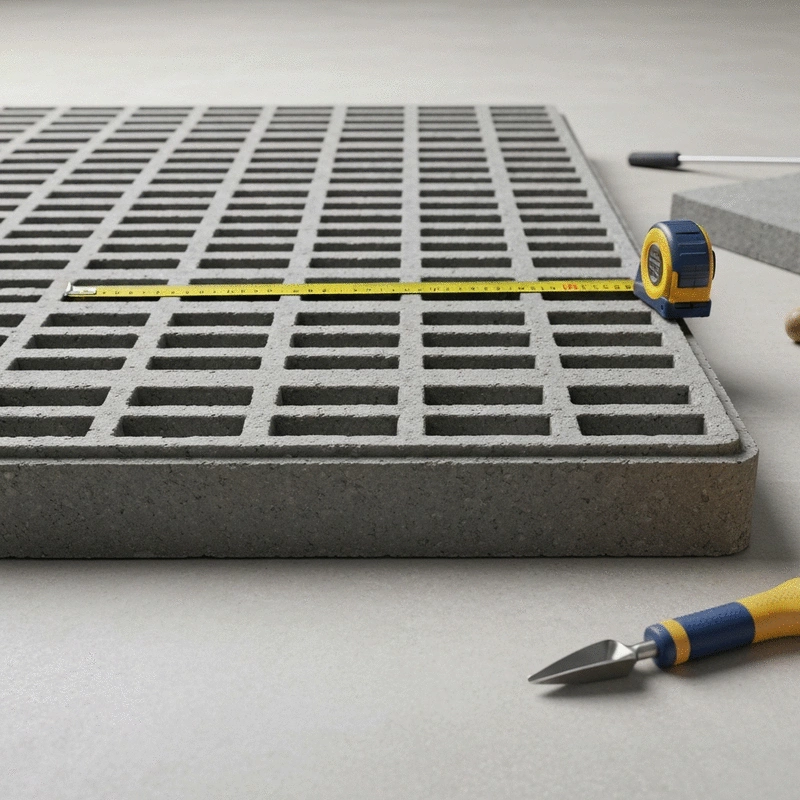

Waffle slab concrete is an innovative building solution that has gained traction in modern construction. It features a grid-like structure that provides both strength and efficiency. By using this design, we can achieve a lighter structure without compromising on load-bearing capacity. This makes waffle slabs an attractive option for various construction needs.

At Concrete Slab Innovations, we see the value that waffle slabs bring to the table. They not only enhance the structural integrity of a building but also optimize concrete usage. Have you considered how this could benefit your next project?

What is Waffle Slab Concrete?

Waffle slab concrete consists of a series of ribs that create a grid pattern, resembling a waffle. This design allows for increased load distribution across the slab, minimizing the amount of concrete needed while maintaining strength. The unique configuration of waffle slabs makes them popular in larger spans, as they can handle significant loads over wide areas.

- Efficient use of materials

- Improved load distribution

- Reduced weight compared to traditional slabs

By incorporating these elements, we can create foundations and floors that are both functional and cost-effective. As an industry expert, I believe that understanding waffle slab concrete is key for any contractor or engineer looking to elevate their projects.

Key Differences Between Waffle Slabs and Waffle Pod Slabs

While both waffle slabs and waffle pod slabs share similarities, they differ in construction and application. Waffle slabs are solid concrete slabs with a grid pattern, whereas waffle pod slabs use lightweight polystyrene pods to reduce concrete volume. This distinction leads to several important differences:

- Weight: Waffle pod slabs are lighter due to the inclusion of pods, making them easier to handle.

- Cost: The use of pods can lower material costs, often resulting in cheaper overall construction.

- Insulation: Waffle pod slabs typically provide better thermal insulation properties.

Choosing the right type for your project often depends on specific requirements, such as load-bearing needs and budget constraints. I'm here to help you navigate these options and find the best fit for your construction endeavors!

The Role of Reinforced Concrete in Waffle Slabs

Reinforced concrete plays a pivotal role in the performance of waffle slabs. By integrating steel reinforcement, we enhance the slab's ability to withstand tension and compression forces. This combination of materials ensures durability and longevity in any construction project. For a deeper understanding of advanced concrete technologies, you can refer to the Federal Highway Administration's chapter on Ultra-High Performance Concrete (UHPC), which highlights similar principles of material optimization and strength.

- Increased strength: Reinforcement helps prevent cracking and structural failure.

- Flexibility: The inclusion of steel allows for greater design flexibility, accommodating various architectural styles.

- Safety: Proper reinforcement contributes to safety standards and building codes.

Understanding how reinforced concrete enhances waffle slabs can greatly influence your project design. As professionals, we must prioritize these considerations to ensure both safety and effectiveness in our builds.

How Waffle Slabs Function: Construction and Design

The construction and design of waffle slabs involve careful planning and execution. By understanding the mechanics behind these structures, we can create efficient and safe building solutions. For instance, detailed guidelines and best practices for concrete design and construction, including information relevant to innovative slab systems like waffle slabs, are often provided by authoritative bodies such as the Bureau of Indian Standards for their construction projects.

Pro Tip

When selecting waffle slab concrete for your project, consider utilizing advanced software for structural analysis and design. This technology not only enhances accuracy but also helps in optimizing material usage, ultimately leading to cost savings and improved safety. By leveraging these tools, you can ensure that your waffle slab design meets all necessary performance criteria while minimizing waste.

Making the Right Choice: Is Waffle Slab Concrete Suitable for You?

When it comes to deciding on the right slab for your construction project, understanding the suitability of waffle slab concrete is crucial. There are several key decision criteria that can help you assess whether this method aligns with your project's needs. Here, I’ll break down three primary considerations: soil conditions, span requirements, and budget constraints.

- Soil Conditions: Assessing the soil type at your construction site is vital. Waffle slabs perform best in stable soils that can adequately support their unique design. For comprehensive insights into various foundation systems and their suitability across different soil types, you may find valuable information in publications such as the Building Materials & Technology Promotion Council's guidelines on foundation systems.

- Span Requirements: Consider the spans you need to cover. Waffle slabs excel in larger spans, making them ideal for open spaces.

- Budget Constraints: Evaluate your financial plan. While waffle slabs may have a higher upfront cost, their long-term benefits often justify the investment.

By examining these factors, you can make a more informed decision about whether waffle slabs fit your construction needs. Remember, if you have any questions or need specific insights, I'm here to help!

Visual Guide to Waffle Slab Installation: Step-by-Step Workflow

To ensure a successful installation of waffle slab concrete, following a structured workflow is essential. Here’s a simple visual guide that outlines the key steps:

- Site Preparation: Begin with clearing and leveling the site to ensure a stable foundation.

- Formwork Setup: Install the aluminum formwork systems to create the waffle patterns. This step is crucial for supporting the concrete during pouring.

- Reinforcement Placement: Position the necessary reinforcement bars within the forms for added strength.

- Concrete Pouring: Pour the concrete mixture into the forms, ensuring even distribution throughout.

- Curing Process: Allow the concrete to cure properly, which is vital for achieving optimal strength and durability.

Following these steps can help streamline the installation process and reduce potential issues. If you want to dive deeper, feel free to reach out for more detailed insights!

Cost Estimation and Project Management for Waffle Slab Projects

Understanding the costs associated with waffle slab construction can seem daunting, but it's manageable with the right approach. Here's what you need to consider:

- Material Costs: Factor in the price of aluminum formwork, concrete, and reinforcement materials.

- Labor Costs: Calculate labor expenses, which can vary based on the complexity of the project and the skill level of your workforce.

- Equipment Rental: Include costs for any machinery or tools needed for the project, such as concrete mixers and cranes.

- Contingency Funds: Always set aside a percentage of your budget for unexpected expenses that may arise during construction.

By effectively estimating these costs and adhering to a solid project management plan, you can ensure that your waffle slab project stays on track and within budget. Should you need assistance navigating these details, I'm just a message away!

Recap of Key Points

Here is a quick recap of the important points discussed in the article:

- Waffle slab concrete features a grid-like structure that enhances load distribution and reduces weight.

- The distinction between waffle slabs and waffle pod slabs lies in the use of polystyrene pods in the latter, impacting weight, cost, and insulation.

- Reinforced concrete increases strength, flexibility, and safety in waffle slab construction.

- Key considerations for using waffle slabs include soil conditions, span requirements, and budget constraints.

- A structured installation workflow is essential for successful waffle slab projects, focusing on site preparation, formwork setup, reinforcement placement, concrete pouring, and curing.

Frequently Asked Questions (FAQs) about Waffle Slabs

- What is the primary advantage of waffle slab concrete?

- The primary advantage is its grid-like structure, which reduces weight while significantly enhancing load-bearing capacity and distributing loads more efficiently.

- How do waffle slabs differ from waffle pod slabs?

- Waffle slabs are solid concrete with a grid pattern, while waffle pod slabs incorporate lightweight polystyrene pods to reduce concrete volume, making them lighter, potentially cheaper, and offering better thermal insulation.

- Why is reinforced concrete important in waffle slabs?

- Reinforced concrete, typically with steel bars, enhances the slab's ability to resist tension and compression forces, increasing strength, flexibility, and overall safety by preventing cracking and structural failure.

- What factors should I consider when deciding if waffle slabs are suitable for my project?

- Key factors include soil conditions (waffle slabs perform best in stable soils), span requirements (ideal for larger, open spaces), and budget constraints (higher upfront costs often justified by long-term benefits).

- What are the main steps in installing a waffle slab?

- The main steps involve site preparation, formwork setup to create the waffle pattern, placement of steel reinforcement, pouring the concrete mixture evenly, and allowing for proper curing to achieve optimal strength.

Popular Posts

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Consider this: the effective use of aluminum formwork can significantly streamline your construction

Consider this: the effective use of aluminum formwork can significantly streamline your construction

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a