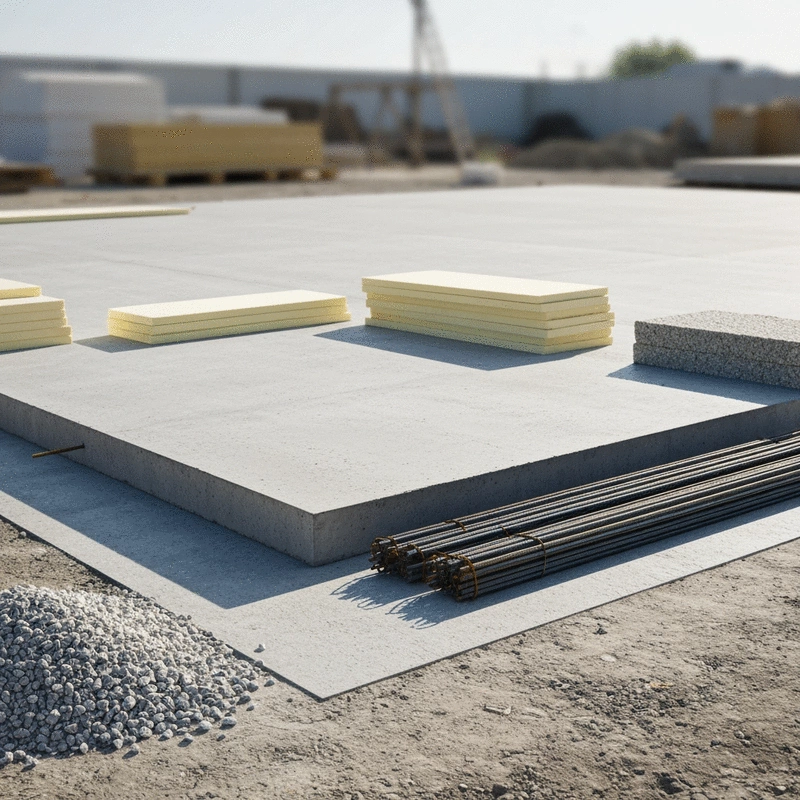

Gravel

Provides a stable base and excellent drainage capabilities. Cost-effective and easy to install with proper compaction.

Choosing the right support materials for concrete slabs can make or break your construction project. Did you know that the foundation directly impacts not only the structural integrity but also the project's overall efficiency? Understanding these materials is key to long-lasting results.

This visual summarizes the primary support materials for concrete slabs, highlighting their unique advantages for construction projects.

Provides a stable base and excellent drainage capabilities. Cost-effective and easy to install with proper compaction.

Enhances load distribution and supports drainage with interlocking angular shapes, improving longevity.

Affordable and easy to apply for smaller projects, but may lack stability for heavy loads without proper compaction.

Modern materials preventing soil erosion, allowing drainage, and maintaining structural integrity in shifting soils.

Improves thermal performance and energy efficiency by reducing heat loss in colder months.

Acts as a vapor barrier, preventing moisture from affecting slab integrity and extending its lifespan.

Essential for reinforcing concrete, providing strength, handling heavy loads, and resisting cracking.

When it comes to concrete slab construction, selecting the right support materials is crucial for achieving a stable and long-lasting foundation. The materials you choose can significantly impact not only the integrity of the slab but also the overall efficiency of your project. Have you ever considered how a solid base can influence your build quality? It’s essential to understand the options available and their implications to make an informed decision.

At Concrete Slab Innovations, we believe that a well-educated contractor or project manager is equipped to tackle the challenges of modern construction. By understanding the various support materials, you can enhance both the safety and sustainability of your projects, which aligns perfectly with our mission of transforming concrete slab construction.

The foundation you lay beneath your concrete slab directly affects its performance. Choosing appropriate support materials ensures that your slab can withstand load capacity, resist cracking, and manage moisture effectively. Not only does this contribute to the longevity of the structure, but it also minimizes maintenance costs down the line. After all, who wants to deal with expensive repairs?

Incorporating the right materials creates a solid foundation that paves the way for successful construction. It’s the difference between a project that lasts and one that requires frequent fixes. So, let’s delve deeper into the types of concrete slab support materials available.

Understanding the various support materials allows for better decision-making. Here are some commonly used materials that every contractor should know:

Now, let's explore these options in detail, starting with gravel, which is often the most popular choice for its reliability and ease of use. Are you ready to elevate your concrete slab projects with the best materials?

Gravel is celebrated for its ability to provide a strong and stable foundation for concrete slabs. It offers excellent drainage capabilities, which are essential in preventing water accumulation that can weaken your structure over time. Plus, the flexibility and ease of installation make gravel a go-to option for many professionals.

One of the highlights of using gravel is its availability and cost-effectiveness. As an experienced contractor, I can tell you that it not only serves as a solid support base but also minimizes the effort required for site preparation. Just remember to compact it properly for the best results!

Crushed stone is another popular support material that provides both stability and effective drainage. Its angular shapes interlock, offering superior load distribution while allowing moisture to flow away from the slab. This can be particularly beneficial in areas with heavy rainfall or poor drainage conditions. Research on the performance of concrete slab systems under various support conditions highlights the importance of materials like crushed stone.

Using crushed stone can also improve the longevity of your slabs, as it helps mitigate the risks associated with excess moisture. If you're looking for a combination of durability and performance, crushed stone is worth considering.

Sand is often used as a base material for smaller projects due to its affordability and ease of application. However, it has its downsides. While it provides a decent temporary base, it may not offer the same level of stability as gravel or crushed stone, especially under heavy loads. Regular compaction is key to maintaining its effectiveness.

Ultimately, sand can be a practical choice for lightweight structures, but for more demanding applications, I recommend exploring the more robust options available.

Geotextiles are modern materials that serve as an excellent barrier against soil erosion while allowing for proper drainage. By using geotextiles, you can prevent the mixing of soil and aggregate, which helps maintain the structural integrity of your slab. This innovative solution can be particularly useful in areas prone to shifting soil conditions.

They can streamline the installation process and enhance long-term performance, making them a worthy consideration for any concrete project.

Foam board insulation is often overlooked in concrete slab projects, but it plays a crucial role in thermal performance. By reducing heat loss during colder months, foam boards help improve energy efficiency and comfort in the buildings above. It's an added layer of protection that can lead to significant energy savings over time!

Incorporating foam board insulation is especially beneficial in climates with extreme temperature variations, ensuring your concrete slabs perform optimally year-round.

Polyethylene sheeting acts as a vapor barrier, preventing moisture from rising through the ground and affecting the slab’s integrity. This is particularly crucial in humid environments where moisture can lead to cracking and other issues. A simple layer of polyethylene can make a significant difference in your project!

By using polyethylene sheeting, you can help to extend the life of your concrete slab while reducing maintenance concerns. It’s a straightforward yet effective solution that shouldn’t be overlooked.

Lastly, we can’t forget about steel rebar and wire mesh, essential for reinforcing concrete slabs. They provide the necessary strength to handle heavy loads and resist cracking, particularly in larger structures. The American Concrete Institute provides extensive information on concrete reinforcement, which is a valuable resource for understanding these materials.

Incorporating these materials improves the overall durability and performance of your concrete, making your slabs not only structurally sound but also reliable in the long run. So, why not consider enhancing your projects with effective reinforcement strategies?

Did you know? Incorporating a combination of gravel and crushed stone can maximize the benefits of your concrete slab's foundation. By layering these materials, you can achieve superior drainage while enhancing load distribution, ultimately leading to a more durable and resilient structure.

A1: Gravel provides a strong, stable base with excellent drainage capabilities, preventing water accumulation and weakening of the structure. It's also cost-effective and easy to install with proper compaction.

A2: While both offer stability and drainage, crushed stone features angular shapes that interlock, providing superior load distribution and enhanced longevity, especially beneficial in areas with heavy rainfall.

A3: Sand is affordable and easy to apply for smaller, lighter projects. However, it may lack the stability for heavy loads compared to crushed stone or gravel, requiring careful compaction to maintain effectiveness.

A4: Geotextiles act as barriers against soil erosion, prevent the mixing of soil and aggregate, and allow proper drainage. They help maintain structural integrity in shifting soil conditions and enhance long-term performance.

A5: Foam board insulation significantly improves thermal performance by reducing heat loss, leading to better energy efficiency and comfort in buildings. It's particularly beneficial in climates with extreme temperature variations.

A6: Polyethylene sheeting functions as a vapor barrier, effectively preventing moisture from rising through the ground into the slab. This helps prevent cracking and extends the slab's lifespan, especially in humid environments.

A7: Steel rebar and wire mesh are crucial for reinforcing concrete slabs, providing the necessary strength to handle heavy loads and resist cracking. They improve the overall durability and structural soundness of the concrete.

When it comes to concrete slab support materials, understanding your options is crucial for ensuring a successful project. Each material plays a specific role in the performance and durability of your slab. From gravel and crushed stone to innovative solutions like geotextiles and foam board insulation, the right choice will depend on your unique project requirements. Let's recap the key benefits of the various materials discussed earlier:

Each of these materials has its advantages, and knowing how they interact within your specific environment will help you make informed decisions.

In conclusion, selecting the appropriate support material is a vital step in concrete slab construction. It’s essential to consider factors like load capacity, environmental impact, and long-term durability. As someone who has worked extensively in this field, I can assure you that the right choice not only supports the structural integrity of your project but also contributes to its sustainability. Whether you are a contractor, engineer, or project manager, the insights I've shared can guide you toward making the best decision for your specific needs.

I encourage you to consult with professionals, such as those at Concrete Slab Innovations, who can provide tailored solutions for your concrete slab projects. Having expert advice ensures that you’re not just choosing a material based on cost but also on how it will perform in the long run. Remember, investing time and effort upfront can save you significant headaches down the road!

Ready to take the next step in your concrete project? Start by finding local suppliers and contractors who can provide quality materials tailored to your needs. Having reliable sources will streamline your process and ensure you have what you need when you need it!

Lastly, don’t forget to explore more resources related to concrete slab design and installation. At Concrete Slab Innovations, we offer extensive guides and case studies to help you navigate through the complexities of concrete construction. Together, we can elevate your projects to the next level!

Here is a quick recap of the important points discussed in the article:

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Consider this: the effective use of aluminum formwork can significantly streamline your construction

Consider this: the effective use of aluminum formwork can significantly streamline your construction

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a