Energy SavingsRecycling Aluminum vs. New Production

95%

less energy required to recycle aluminum compared to producing new aluminum from ore.

What if the future of construction lies in lightweight materials that not only enhance efficiency but also contribute to sustainability? Load-bearing aluminum formwork is revolutionizing high-rise projects, offering solutions that cater to modern architectural demands.

A visual comparison of key environmental benefits offered by aluminum formwork in high-rise construction.

95%

less energy required to recycle aluminum compared to producing new aluminum from ore.

In the realm of high-rise construction, load-bearing aluminum formwork has emerged as a critical component that shapes the efficiency and safety of building practices. But what exactly is it? This innovative system utilizes lightweight aluminum panels that can support considerable weight during the concrete pouring process, making it ideal for skyscrapers and other tall structures.

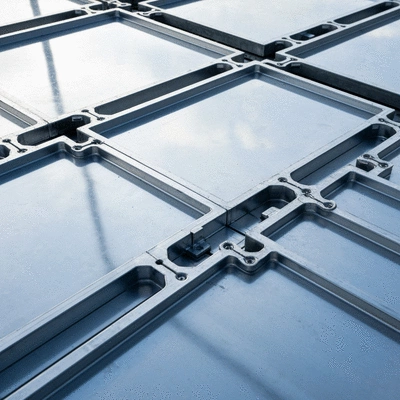

When we talk about aluminum formwork, we're referring to a modular construction technique that simplifies the pouring and curing of concrete slabs. Each panel interlocks seamlessly to create forms that can withstand the pressures of wet concrete, all while maintaining precision in shape and size. As someone who's passionate about innovative building solutions, I've witnessed firsthand how this technology transforms project outcomes!

Load-bearing aluminum formwork consists of pre-engineered panels designed to serve as both temporary molds for concrete and structural supports until the concrete sets. This dual functionality not only streamlines the construction process but also minimizes the need for additional support systems. The unique aspect of aluminum formwork is its ability to be reused multiple times, providing substantial savings for contractors and engineers alike. For a detailed exploration of its benefits, this study on aluminum formwork advantages offers valuable insights.

This blend of features makes aluminum formwork an attractive choice for high-rise projects, where structural integrity and efficiency are paramount. It’s fascinating how such advancements can influence the overall success of a building project!

Using aluminum formwork in high-rise construction is not merely a trend; it's a necessity driven by the demands of modern architecture. As buildings grow taller and more complex, the need for robust, yet flexible, construction solutions becomes increasingly evident. Aluminum formwork meets this demand by offering a combination of strength and adaptability.

These advantages underscore how adopting aluminum formwork can lead to not only enhanced project outcomes but also increased profitability for contractors. If you’re in the construction field, wouldn't you want to leverage such tools for your high-rise projects?

Innovations in aluminum formwork systems have revolutionized how we approach high-rise construction. One notable advancement is the implementation of modular designs that allow for quick assembly and dismantling. This means projects can move forward at a rapid pace, which is critical in today’s fast-paced construction environment. Further details on the impact of aluminum formwork on construction efficiency can be found in this informative paper.

As an industry expert, I’m excited about these innovations because they not only elevate safety standards but also promote economic sustainability. Embracing these advancements can position construction professionals, like those at Concrete Slab Innovations, as leaders in the field of modern building solutions.

What do you think about the adoption of aluminum formwork in high-rise construction? Share your thoughts below:

As we strive towards a more sustainable future in construction, the environmental benefits of aluminum formwork are becoming increasingly significant. At Concrete Slab Innovations, we’re dedicated to promoting practices that not only enhance project efficiency but also reduce our carbon footprint. So, how exactly does aluminum formwork contribute to sustainability in high-rise construction?

By adopting aluminum formwork systems, we can contribute to a greener construction industry. This not only benefits our environment but also enhances our reputation as responsible builders!

Reducing the carbon footprint in construction is a critical goal, and aluminum formwork plays a vital role in achieving this. Unlike traditional materials, aluminum is highly efficient in its usage and requires less energy to produce. Here are some ways aluminum helps in reducing emissions:

Incorporating these practices not only reflects a commitment to sustainability but also drives overall project success by adhering to evolving environmental standards!

Aluminum is one of the most recyclable materials available today. When we choose aluminum formwork, we foster a culture of recyclability that benefits the entire construction lifecycle. Here’s how:

This commitment to recyclability encourages innovation in construction practices and highlights the importance of sustainability in our industry.

At Concrete Slab Innovations, we actively promote sustainable construction practices throughout our projects. High-rise developments, in particular, benefit from these strategies:

By incorporating these sustainability practices, we not only enhance our environmental responsibility but also contribute to the longevity and value of our high-rise projects. Together, we can redefine the standards of modern construction!

A1: Load-bearing aluminum formwork is a modular construction system using lightweight aluminum panels that serve as temporary molds for concrete and structural supports until the concrete sets. It's designed to streamline construction processes and is ideal for high-rise buildings due to its high load capacity and reusability.

A2: Aluminum formwork contributes to sustainability by reducing carbon emissions due to its lightweight nature (less transportation impact) and its high recyclability. Recycling aluminum requires significantly less energy than producing new aluminum, and the formwork itself can be reused multiple times, reducing material waste.

A3: The main advantages include faster construction timelines, reduced labor requirements and associated costs, enhanced safety on-site, and improved quality control in concrete pouring. Its modular design also allows for quick assembly and dismantling.

A4: Yes, one of the key benefits of aluminum formwork is its ability to be reused multiple times across different projects, which leads to substantial cost savings and waste reduction.

A5: Modern aluminum formwork systems feature innovations such as modular designs for rapid assembly, automated systems for precise alignment, integration of smart technologies for monitoring, enhanced customization options, and improved environmental resistance for greater longevity.

Here is a quick recap of the important points discussed in the article:

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Have you ever considered how choosing the right formwork can significantly impact your project's eff

Consider this: the effective use of aluminum formwork can significantly streamline your construction

Consider this: the effective use of aluminum formwork can significantly streamline your construction

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

What if the key to revolutionizing your construction project lies in the materials you choose? Alumi

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a

As high-rise construction evolves, aluminum formwork is emerging as a game-changer for contractors a